PlanetCNC Software

PlanetCNC TNG software is a comprehensive tool designed to enhance the operation of CNC machines. This software is versatile and supports a variety of file formats and features to ensure CNC operations are efficient and accurate. Here's an easy-to-understand overview of what PlanetCNC TNG offers.

Key Features of PlanetCNC TNG Software

1. Compatibility with Standard G-Code:

PlanetCNC TNG can open standard G-code files that are compatible with other CNC software like Mach, LinuxCNC, and Fanuc. This makes it easy to use files created in different systems.

2. File Import and Export Options:

Import: The software can import various file types including DXF, HPGL, SVG, Gerber, NC-drill (Excellon), images, and CSV files. This allows users to work with designs and data from many different sources.

Export: Users can export their projects as G-code, DXF, or CSV files, making it simple to share or further process their work in other tools.

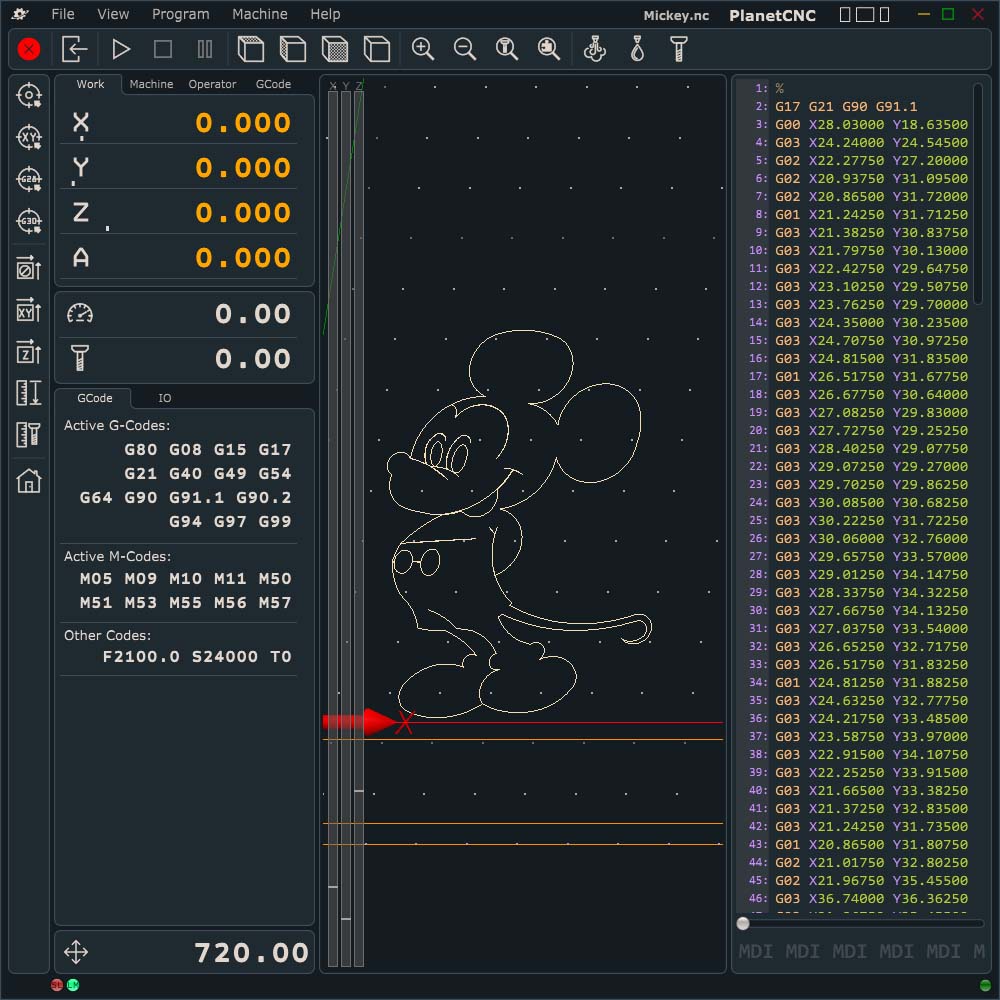

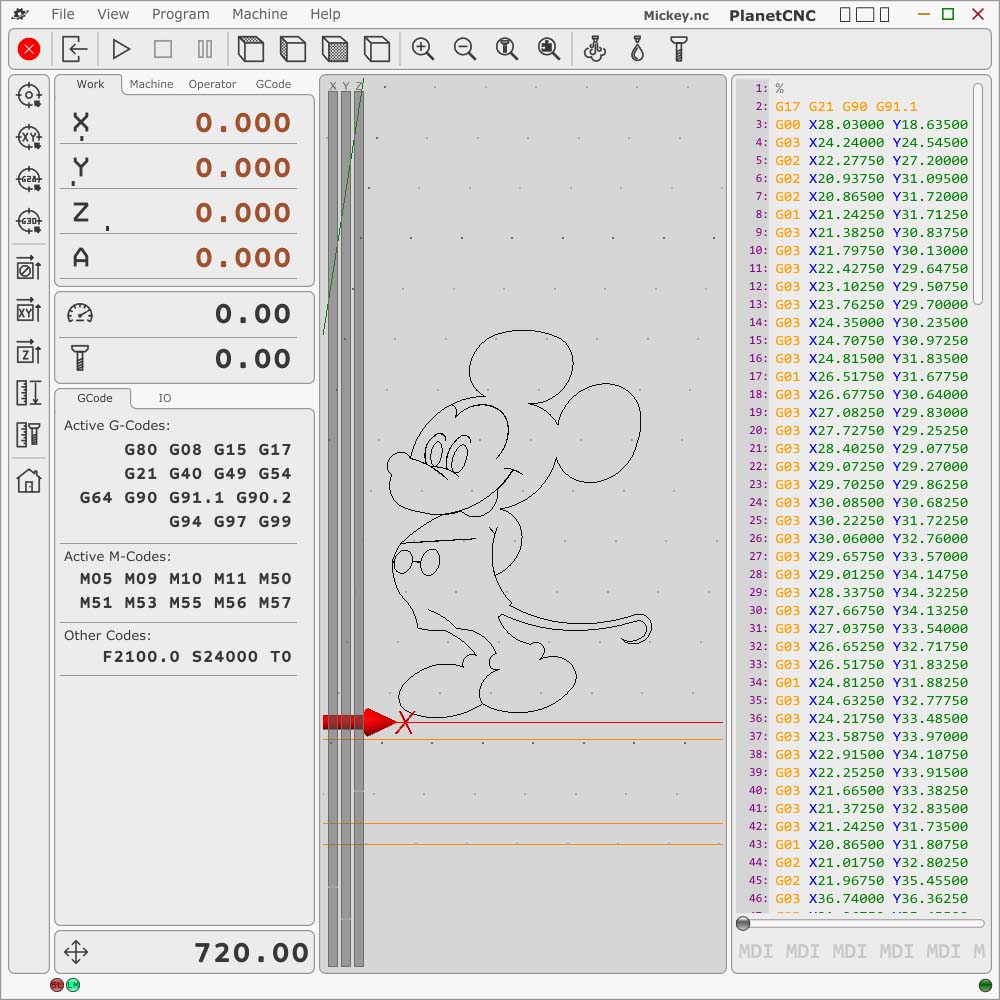

3. Advanced Visualization Tools:

PlanetCNC TNG displays the toolpath in 3D, allowing users to zoom in/out, center, and follow the toolpath as the machine processes the material.

It also visualizes the entire CNC machine in 3D, helping operators to better understand and control the machine’s movements.

4. G-Code Editing and Manipulation:

The software enables searching, marking, and bookmarking specific lines of G-code, which simplifies making changes or finding parts of the code quickly.

Users can transform, shift, translate, scale, and rotate the toolpath. It’s also possible to adjust the toolpath based on sampled points from the material surface.

PlanetCNC TNG can warp G-code to fit uneven surfaces, which is particularly useful for complex, non-standard projects.

5. Machine Control Functions:

Operators can start, stop, emergency stop, and pause the machine directly through the software, giving them full control during the machining process.

The software can initiate operations from a selected line, position, bookmark, or mark. It also supports running multiple loops, enhancing the flexibility and automation of repetitive tasks.

6. Support for Machine Functions:

The software manages outputs like coolant (flood and mist) and spindle control.

It also supports various inputs used for probing, measuring, and homing the machine.

Users can override speed and feed settings directly within the software, adapting quickly to different machining conditions.

PlanetCNC TNG handles working offsets, different coordinate systems, and tool offsets, which is crucial for precision in CNC machining.

A tool table with extensive tool attributes is available, aiding in precise setup and operation.

7. Additional Features:

The software can calculate feed and spindle speeds based on the tool and material type, optimizing cutting conditions.

It supports all types of measurements with a probe and can even integrate measurements taken with a camera.

PlanetCNC TNG is fully scriptable using G-code, and it includes a powerful built-in scripting language called Expr, allowing users to customize functionality according to their specific needs.

It supports integration through C API and/or Python, making it highly adaptable for custom applications.

An interactive help feature is included to assist users in learning and using the software effectively.

Conclusion

PlanetCNC TNG software is a powerful, user-friendly tool for anyone using CNC machinery. With its wide range of compatible file types, detailed visualization capabilities, and extensive machine control options, it is designed to enhance productivity and precision in CNC operations. Whether you are a beginner or an experienced CNC operator, PlanetCNC TNG offers the tools and flexibility needed to create high-quality machined products efficiently.